Subsurface remediation work inevitably involves uncertainty. Variations in geology, limited data density, and evolving site conditions make it difficult to predict contaminant behaviour or ensure complete amendment distribution.

To help address these challenges, VEI Contracting has adopted the Environmental Site Model (ESM®) — a digital software platform originally developed by Ejlskov and used throughout the RPI Group to manage, visualize, and interpret subsurface environmental data. ESM® enables teams to design, visualize, and dynamically track in-situ remedial injection programs in both two and three dimensions, integrating high-resolution site characterization, remedial design, and field implementation data within a single, interactive platform.

ESM® functions as a centralized conceptual site modeling and project management tool that can be used across all project stages:

- Desktop mode for remedial designers;

- Tablet mode for field personnel capturing real-time injection data; and

- Viewer mode for clients, regulators and other stakeholders reviewing progress.

The platform can integrate GIS and LiDAR terrain data, borehole and monitoring well logs, and high-resolution site characterization (HRSC) outputs such as Laser Induced Fluorescence (LIF), Membrane Interface Probe (MIP) and Hydraulic Profiling Tool (HPT) data. These inputs are rendered into detailed 2D cross-sections and 3D volumetric models that display stratigraphy, contaminant distribution, and hydraulic conductivity patterns.

Originally designed as a simple but comprehensive environmental information system, ESM® supports the entire lifecycle of remediation projects – from early investigation and data gap analysis through remedial design and optimization, injection implementation, and long-term monitoring. The same model used for design becomes the framework for interpreting performance data, ensuring continuity and transparency throughout a project’s duration.

Remedial design traditionally relies on sparse datasets and static figures. ESM® brings those data sets to life by integrating and spatially aligning geological, hydrogeological, and chemical information.

Its main advantages include:

- Improved visualization of subsurface conditions, helping to define targeted treatment zones more completely;

- Integration of HRSC data, providing higher-resolution, 3D conceptual site models that drive remedial injection programs;

- Real-time tracking of injection activity, ensuring field crews adhere to design intent while accommodating field variability; and

- Efficient communication among office staff, field teams, and stakeholders, with consistent data representation.

Functionally, ESM® acts as a living Conceptual Site Model (CSM) – a continuously updated representation of the site that evolves as new data are collected. This alignment with standard CSM practice helps refine understanding of contaminant mass/flux, pathways, and treatment effectiveness, directly reducing uncertainty during in-situ remedial programs.

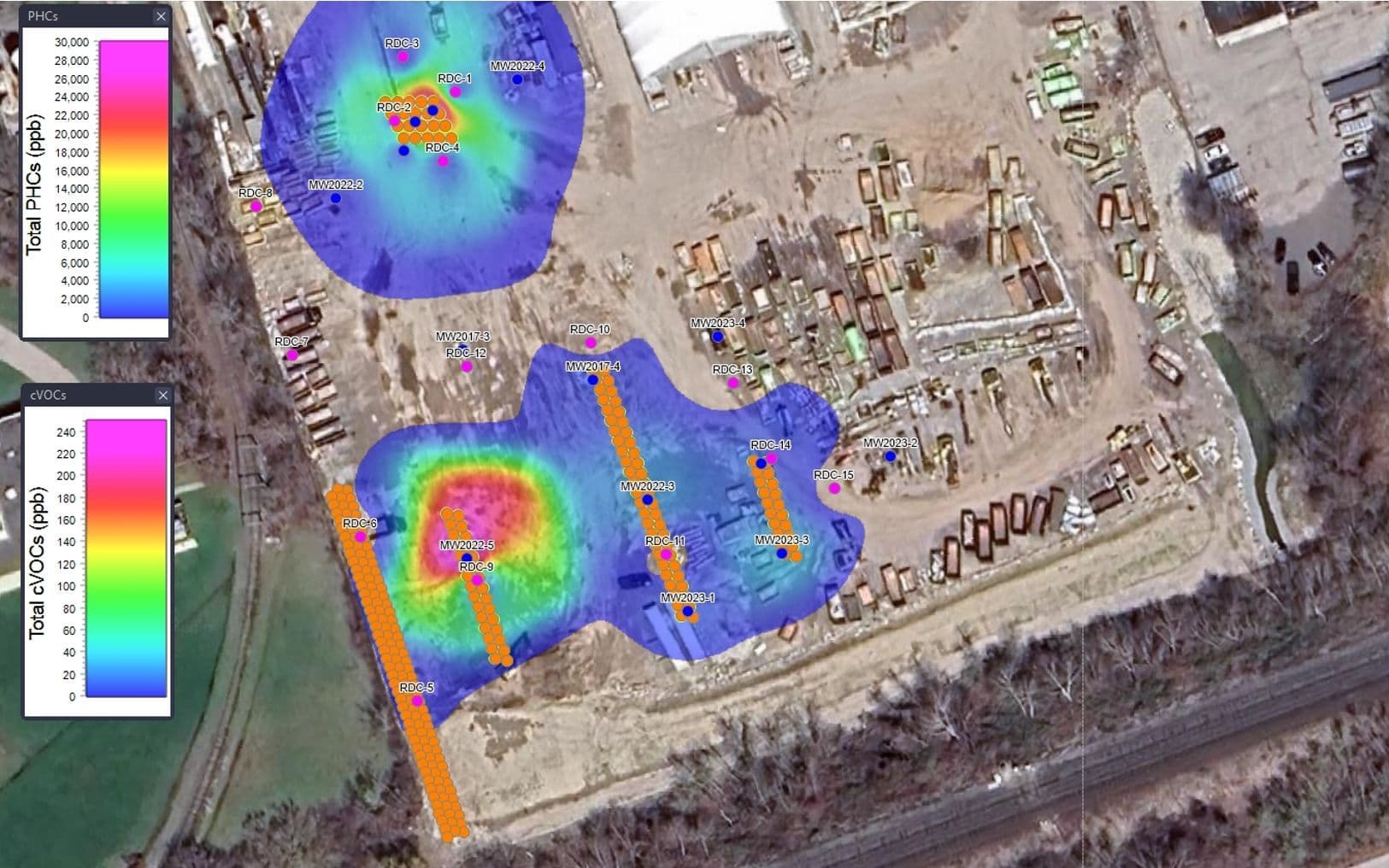

At one GTA site, ESM® supported the remediation of chlorinated volatile organic compounds (cVOCs) and petroleum hydrocarbons (PHCs) in groundwater. Impacts originated from historic underground storage tanks combined with a migrating cVOC plume from an adjacent property.

The goals were to:

- Enable future commercial redevelopment;

- Address environmental issues required for financing; and

- Manage liability associated with the upgradient contaminant source.

Approach:

Using ESM®, the design team developed a multi-tiered injection plan that combined:

- Trap and Treat® BOS 100® (activated carbon and elemental iron) to intercept chlorinated solvent migration,

- Zero-valent iron (ZVI) zones to treat dissolved-phase cVOCs within the property, and

- Trap & Treat® BOS 200+® (activated carbon with terminal electron acceptors (TEAs), nutrients and microbes) for localized PHC-impacted areas.

ESM® visualizations defined injection zones and allowed for real-time tracking during field implementation. The program comprised approximately 250 injection points and 130,000 L of reagent slurry across several treatment zones.

Results:

Four months post-injection, groundwater monitoring showed:

- 41–100% reductions in cVOCs, including complete removal of cis-1,2-dichloroethylene (DCE); and

- 92–94% reductions in PHCs within the localized source zone.

By combining remedial design characterization (RDC) and live field data, ESM® helped confirm reagent coverage and performance trends, shortening the adjustment cycle typical of large-scale in-situ programs.

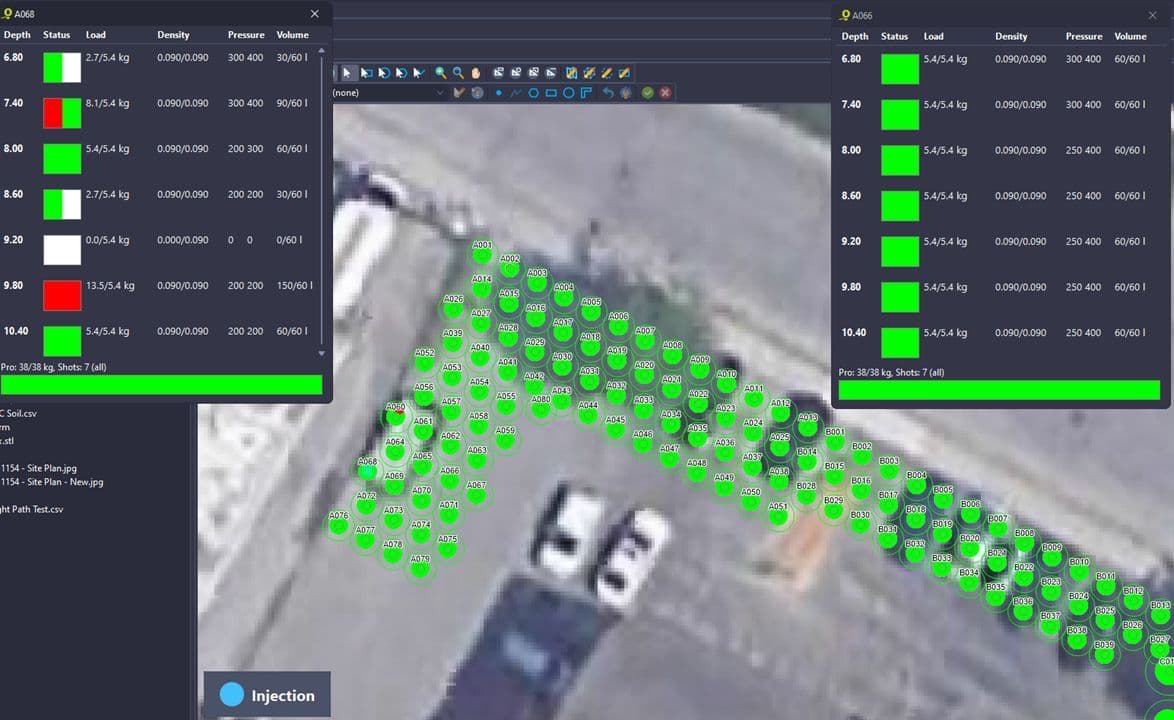

A second application involved the design of a Permeable Reactive Barrier (PRB) to intercept an upgradient chlorinated solvent plume. Only two monitoring wells and limited geological data were initially available.

To strengthen the CSM, VEI completed a HRSC and RDC program using MiHPT (combined MIP and HPT) targeted borings, producing thousands of measurements of contaminant concentration, stratigraphy, and subsurface permeability.

These results were imported into ESM® and converted into 3D volumetric mass models showing contaminant distribution and hydraulic conductivity. This allowed the design team to position the PRB precisely, define injection spacing, and calculate required reagent loadings with greater certainty than conventional methods.

The optimized design included approximately 160 injection points and approximately 75,000 L of BOS 100® slurry. During injection, data were logged directly into ESM®, capturing both spatial coverage and reagent delivery metrics. The system’s time-based playback function enabled visualization of injection progress and provided a permanent digital record of field execution – useful for future performance verification and liability management.

While post-remediation monitoring was still underway, early field feedback indicated consistent subsurface coverage and well-defined reactive zones, validating the approach and highlighting the usefulness of integrating HRSC and modeling tools during the design phase.

Improving Decision-Making and Documentation

Beyond visualization, ESM® functions as a data management and decision-support system. By organizing subsurface datasets spatially, it allows remedial designers to:

- Compare injection logs against modeled geology;

- Identify zones of reduced permeability or incomplete coverage; and

- Adjust future injection parameters based on observed conditions.

Because ESM® records injection location, sequence, and volume over time, it also serves as a defensible record of remedial activity. The ability to replay field operations and link them to monitoring results improves accountability and facilitates clearer communication with clients, regulators, and financial institutions – an increasingly important requirement for brownfield redevelopment and risk-management projects.

A Platform for Collaboration

ESM® enhances collaboration between disciplines that often work in parallel.

- Field personnel can visualize real-time progress relative to modelled conditions;

- Designers can monitor data as it is collected and make immediate refinements; and

- Clients, regulators and other stakeholders gain a clear understanding of subsurface activity without relying solely on static figures, tables and reports.

%2520(1).jpg&w=3840&q=75)

This shared digital environment improves alignment between design and implementation, reducing the disconnects that can arise between conceptual design and field execution.

The Environmental Site Model® is now part of VEI’s workflow for all in-situ remediation projects in Canada. Its integration of high-resolution data, spatial modeling, and live injection tracking helps transform raw data into actionable insight.

Key benefits include:

- Stronger, continuously updated conceptual site models;

- Better definition of treatment zones and reagent volumes;

- Real-time visualization and documentation of injection progress; and

- Improved coordination among designers, field crews, and stakeholders.

By maintaining a single digital framework from investigation through monitoring, ESM® provides a more transparent and technically grounded basis for designing and validating in-situ remediation programs – reducing uncertainty and improving the predictability of outcomes.